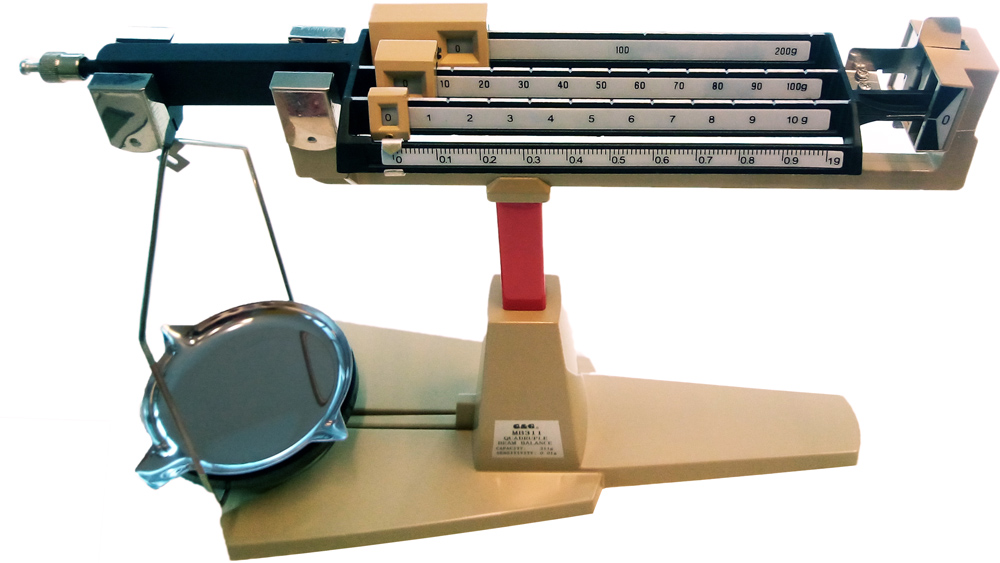

MB-311 Sliding weight scales, beam scales, mechanical precision scales

• Weighing range up to 311 grams; Readability 0.01 grams

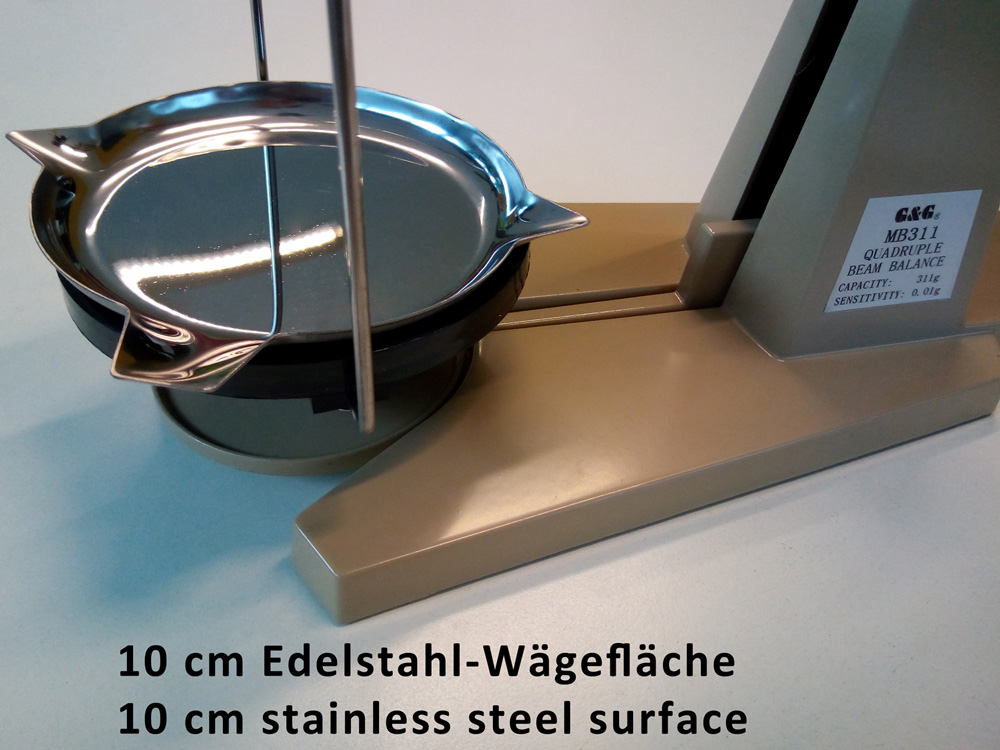

• Metal version: cast iron, steel and stainless steel.

• Stabilization through magnetic damping;

• central weight reading; Stainless steel weighing surface

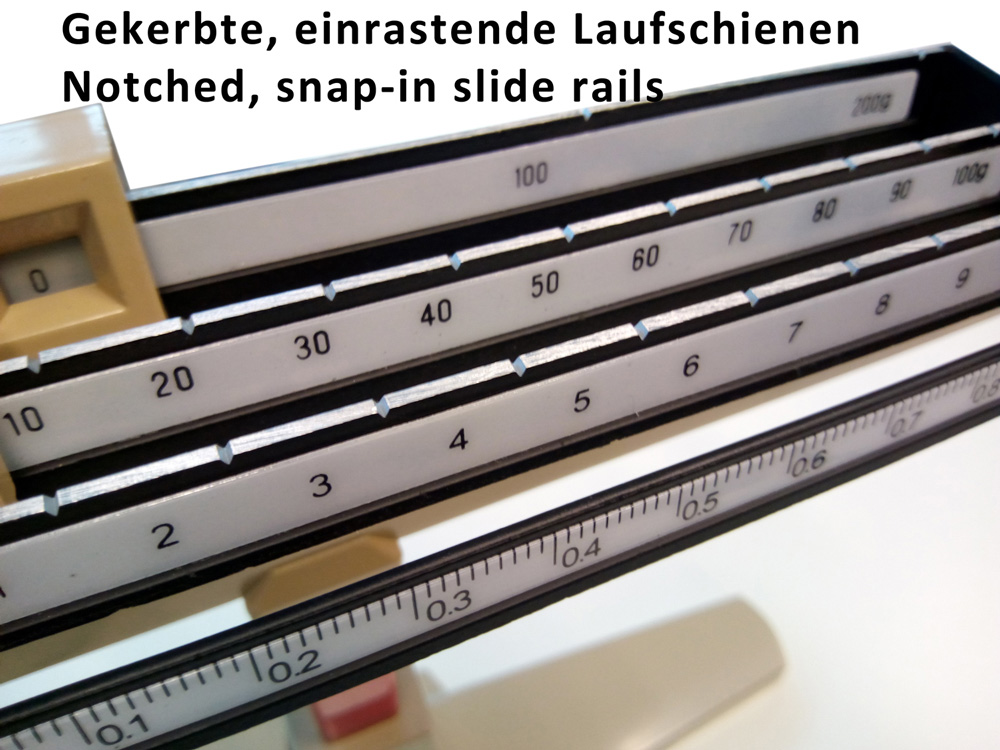

• 3 sliding weights on a notched weighing beam

• Metal design: With the exception of the support for the weighing surface (plastic) and the high-quality ceramic plain bearings, the scale is made entirely of steel, stainless steel or cast aluminum.

Beam scales are among the oldest scales of mankind. The first examples were found during excavations in Egypt and date from around 5000 BC. Chr.

Roman scales from Pompeii, after having been freed from the remains of the volcanic eruption, still function without any problems today.

The measuring principle of the scale is leverage.

Gravity pulls the object to be weighed down on the short side of the lever. Three weights can be pushed into different positions on the lever. This is where the name sliding weight or pushin weight scale comes from. The further the barrel weight is pushed to the right (away from the pivot point), the greater the leverage. If a 10g weight was placed on the left, a 1g running weight brings the balance beam into the horizontal position if it is 10 times as far from the pivot point as the larger weight.

The MB311 has a total of 4 weighing beams with different weights. The weight can be shifted in 100g, 10g and 1g steps using the three largest bars. The bars have a notched tread, in which the weights can be felt to snap into place and thus enable a very quick and comfortable setting with an accuracy of 1g.

The scales are fine-tuned using the bottom bar, on which the smallest running weight can be positioned with a scale of 0.01g increments:

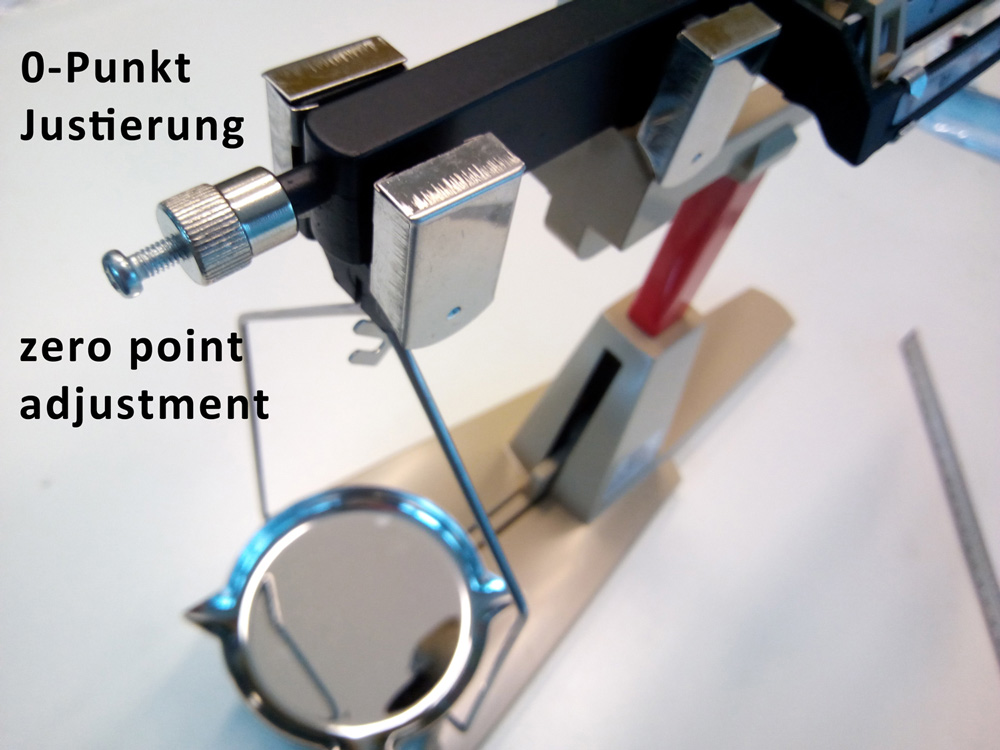

The precise 0 position (horizontal position without any load on the weighing surface) can be adjusted using an adjusting screw.

The weighing surface is made of stainless steel, is removable and, in addition to the handle, also has two chutes with which, for example, powder can be conveniently removed to the left and right.

Mechanical scales only have a tiny market position compared to their digital descendants.

The models are only partially suitable for weighing a solid object. With a digital scale, you place the object on the weighing surface and read the calculated weight on the display. With mechanical scales, the running weights have to be pushed back and forth until the bar remains in a horizontal position. Then the position of the individual barrel weights is read and added in the head.

This no longer fits into today's world in which "time has become money". Most of the models are not used for weighing, but are used for educational purposes in school lessons.

To this day, mechanical scales are almost unbeatable for one task, namely when weighing to a known weight.

When dispensing, you have to add something to a digital scale and at the same time keep an eye on the display. That means, wait until the display has calmed down and is stable, fill in something again, read off the weight again, pour something more and so on ...

On the MB, slide the sliding weight to the desired position and fill in until the weighing pan lowers. There is no display to watch out for and you will never find out that the batteries are empty exactly when you need the scale most urgently.